Inconel is a family of austenitic nickel-chromium-based superalloys.

Inconel is resistant to oxidation and corrosion, making it ideal for use in extreme environments subject to pressure and heat. When heated, Inconel forms a thick, stable, passivating oxide layer that protects Inconel and maintains its strength over a wide temperature range, making it attractive for high temperature applications.

Inconel series: 600,601,617,625,690,718,X-750,825

| Item | 600 | 601 | 617 | 625 | 690 | 718 | x-750 | 825 |

| C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

| Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

| Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

| P | ≤0.015 | ≤0.02 | ≤0.015 | – | – | – | – | – |

| S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

| Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

| Cu | ≤0.5 | ≤1 | – | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

| Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | – | 38-46 |

| Co | – | – | 10-15 | ≤10 | – | ≤1 | ≤1 | – |

| Al | – | 1-1.7 | 0.8-1.5 | ≤0.8 | – | 0.2-0.8 | 0.4-1 | ≤0.2 |

| Ti | – | – | ≤1.15 | ≤1.15 | – | 2.25-2.75 | 0.6-1.2 | |

| Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

| Nb+Ta | – | – | 4.75-5.5 | – | 4.75-5.5 | 0.7-1.2 | – | |

| Mo | – | – | 8-10 | 2.8-3.3 | – | 2.8-3.3 | – | 2.5-3.5 |

| B | – | – | ≤0.006 | – | – | – | – |

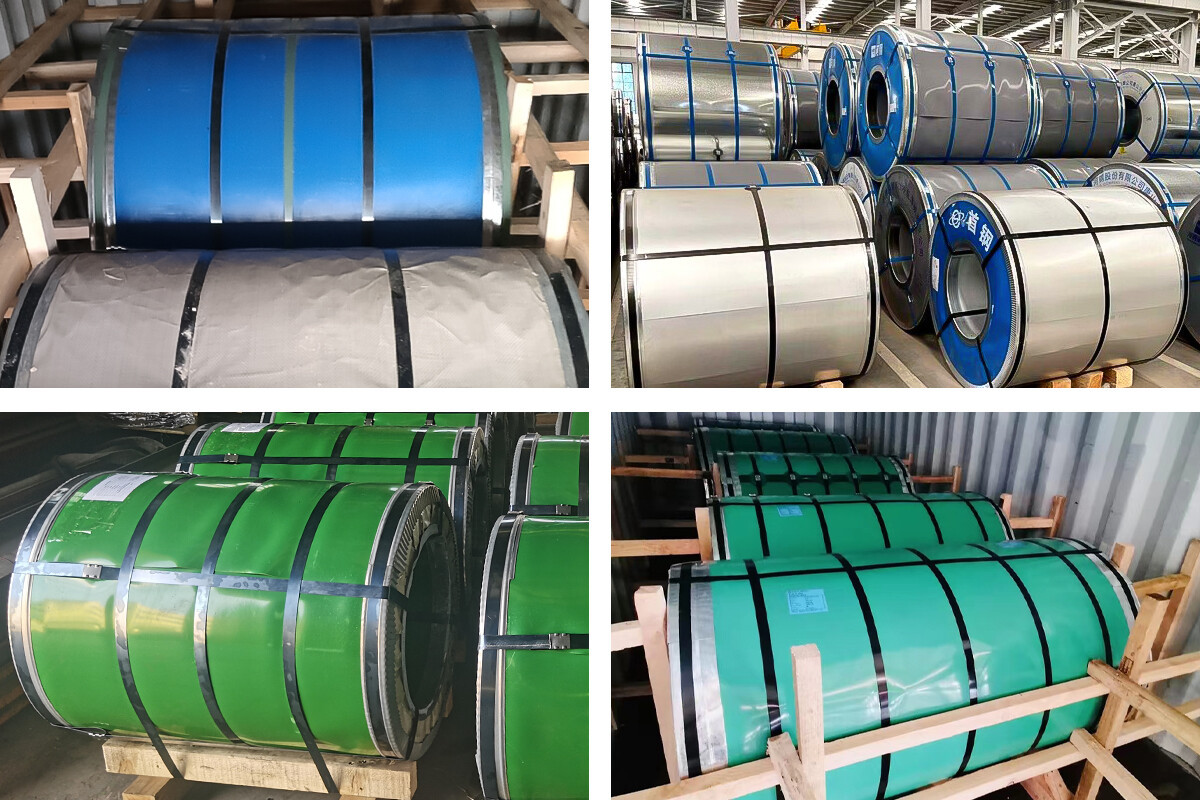

Packaging and Transportation

PACKAGE:

Standard export seaworthy packing.

DELⅣERY TIME:

3-20 days after confirming order, detail delivery data should be decided according to production season and order quantity.

Products Applications